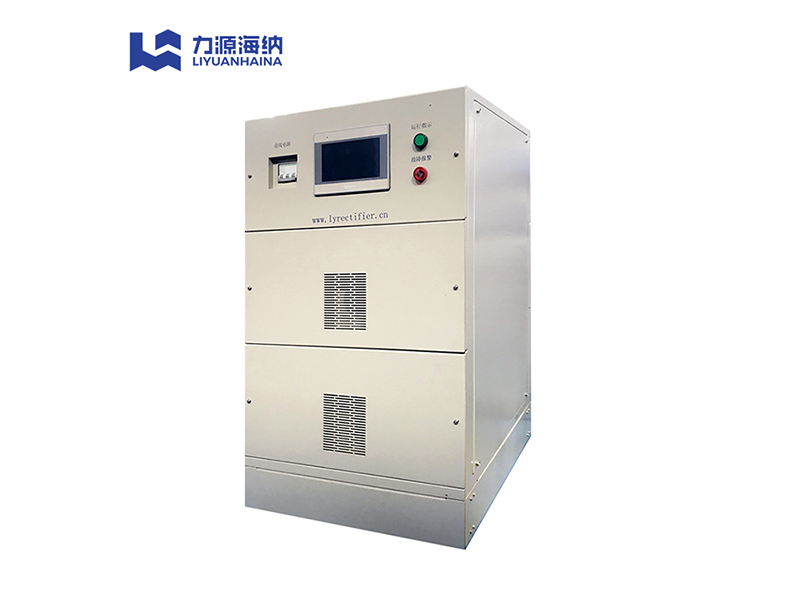

The customer's factory is in Peru and is a professional metal processing factory. The customer started the first order for hard chrome plating ±15V10000A with polarity conversion in 2021 to improve the wear resistance and corrosion resistance of metal parts.

Using a rectifier with polarity conversion can provide a more stable electroplating current, which is very important for ensuring the quality of the plating.

2024.08 The customer has a new demand for two rectifiers with polarity conversion and two water coolers. The water cooler is used to cool the plating solution during the electroplating process to maintain a constant temperature, which is crucial for the stability of the electroplating process and the quality of the final product.

In October 2024, we visited the factory and discussed further cooperation to understand the effect of the factory using our rectifiers and solve some problems for customers during use.

Hot Tags:Hard Chrome Plating Rectifier Project,hard chrome plating ±15V10000A with polarity conversion,water coolers,metal processing factory,Peru